Landline:+86-0775-84649797 Phone:+86 19926651112(Same WeChat ID)

Share:

RFID makes the piano management more and more standardized

With the development of informatization, modern manufacturing enterprises are adopting more intelligent production management methods. Piano factories are also turning to RFID technology for label identification management. This is due to the difficulty of cross-regional goods transfer and the need for product label reading, which cannot be met by traditional barcode technology. Raw material management and quality control are also big challenges in piano production, which can affect the company's reputation, after-sales service, and work efficiency.

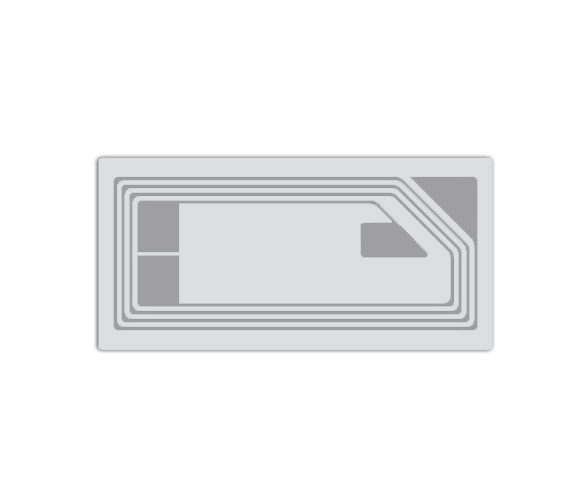

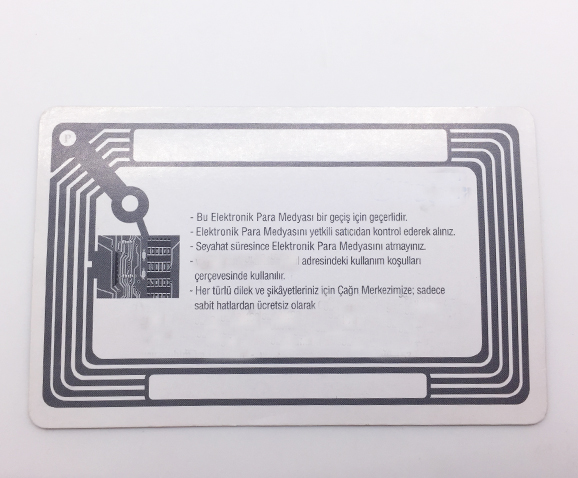

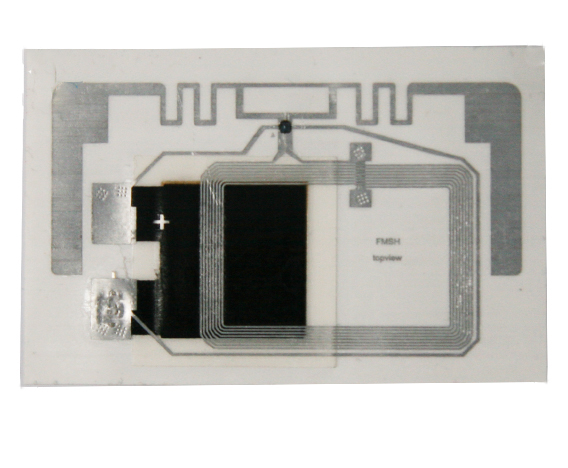

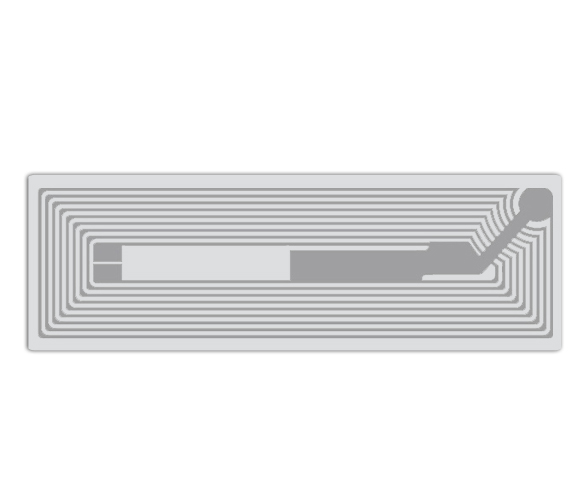

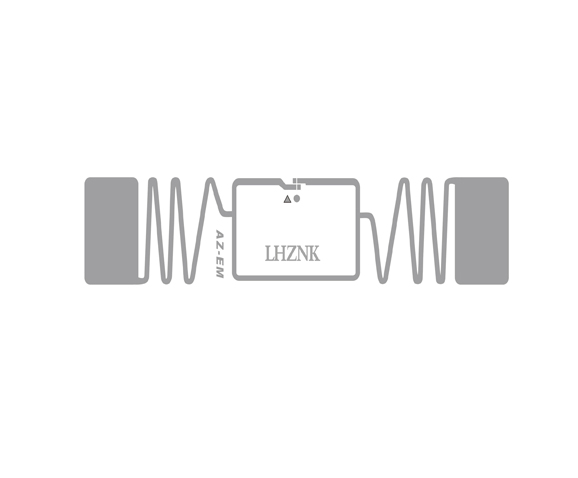

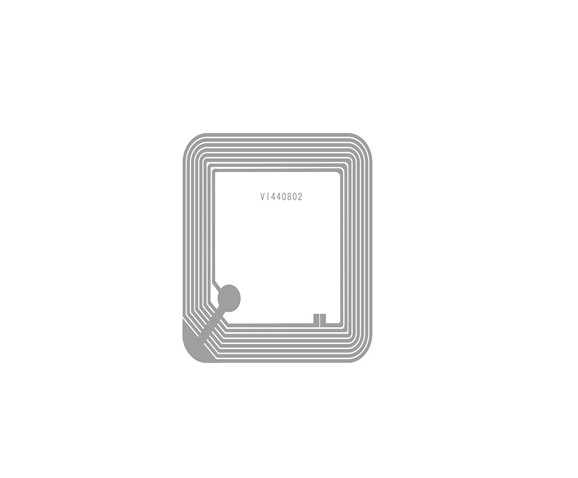

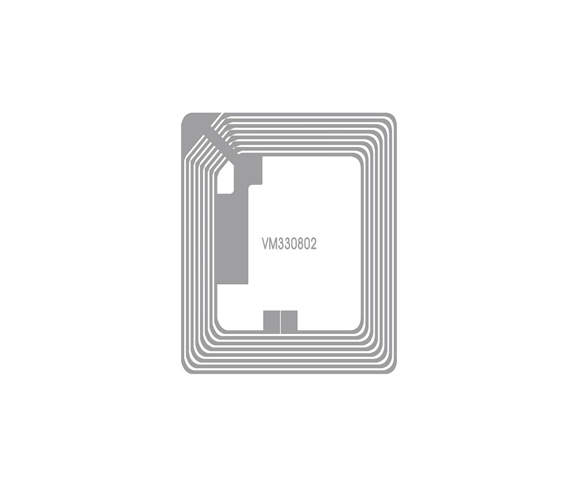

Union Smart provided RFID electronic tags and reader to a piano factory to improve their RFID management system. RFID technology enables piano factories to track pianos throughout the entire process, from raw material procurement to finished piano shipment, in real-time. This improves production efficiency, reduces costs, and enhances management and quality control.

RFID technology helps piano factories track and manage raw materials by attaching RFID tags to them. This allows for real-time tracking of the quantity, location, status, and source of raw materials, optimizing inventory management and increasing production efficiency. RFID technology also has a batch reading function, reducing the time for collecting product information and improving the efficiency of piano factory production, warehouse, and transportation management.

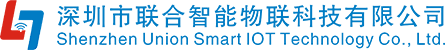

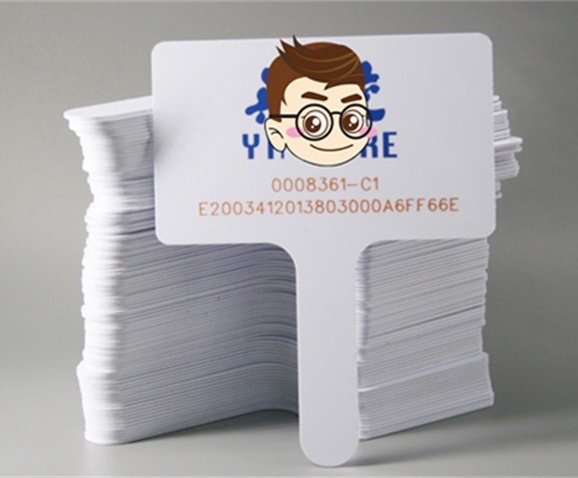

In the last article, we mentioned that Union Smart provided RFID electronic tags and reading equipment for a piano factory. The addition of RFID technology can not only improve production efficiency and reduce costs, but also play an anti-counterfeiting and anti-piracy role.This helps companies achieve strict supervision and control over the orderly flow of key commodities in the distribution network, improving channel management and after-sales efficiency, and reducing and avoiding channel risks. The system uses RFID electronic tag technology to accurately and confidentially identify key commodities with globally unique UID. Through the product verification function of foreign branches, the problem of cross-regional sales and barcode channeling can be effectively eliminated, and the impact of counterfeiting can be prevented.

Union Smart provided RFID electronic tags and reader to a piano factory to improve their RFID management system. RFID technology enables piano factories to track pianos throughout the entire process, from raw material procurement to finished piano shipment, in real-time. This improves production efficiency, reduces costs, and enhances management and quality control.

RFID technology helps piano factories track and manage raw materials by attaching RFID tags to them. This allows for real-time tracking of the quantity, location, status, and source of raw materials, optimizing inventory management and increasing production efficiency. RFID technology also has a batch reading function, reducing the time for collecting product information and improving the efficiency of piano factory production, warehouse, and transportation management.

In the last article, we mentioned that Union Smart provided RFID electronic tags and reading equipment for a piano factory. The addition of RFID technology can not only improve production efficiency and reduce costs, but also play an anti-counterfeiting and anti-piracy role.This helps companies achieve strict supervision and control over the orderly flow of key commodities in the distribution network, improving channel management and after-sales efficiency, and reducing and avoiding channel risks. The system uses RFID electronic tag technology to accurately and confidentially identify key commodities with globally unique UID. Through the product verification function of foreign branches, the problem of cross-regional sales and barcode channeling can be effectively eliminated, and the impact of counterfeiting can be prevented.

Inquiry