Landline:+86-0775-84649797 Phone:+86 19926651112(Same WeChat ID)

Share:

RFID—the key to unlocking the efficient operation of production lines

Modern manufacturing industry is facing increasingly fierce market competition, and the efficient operation of production lines is key to gaining a competitive advantage. In this digital age, RFID technology serves as a key to unlock efficient production line operations, leading the manufacturing industry towards intelligent transformation.

1. RFID technology provides automated material management and tracking for production lines:

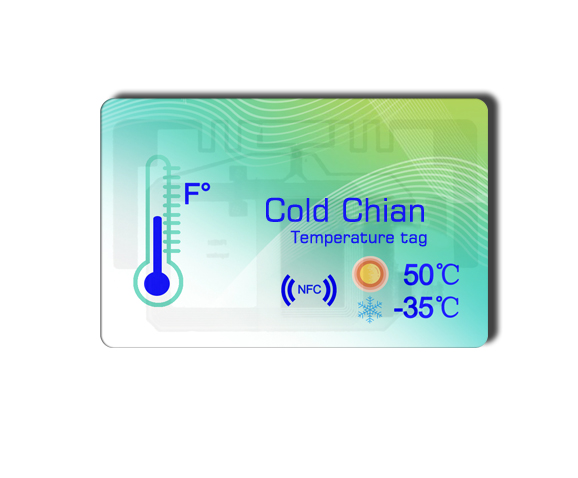

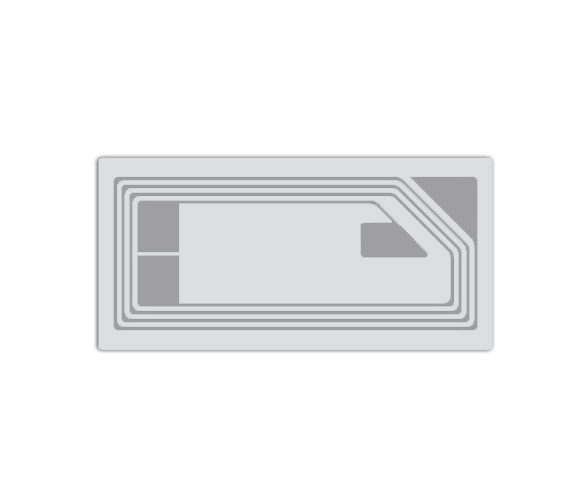

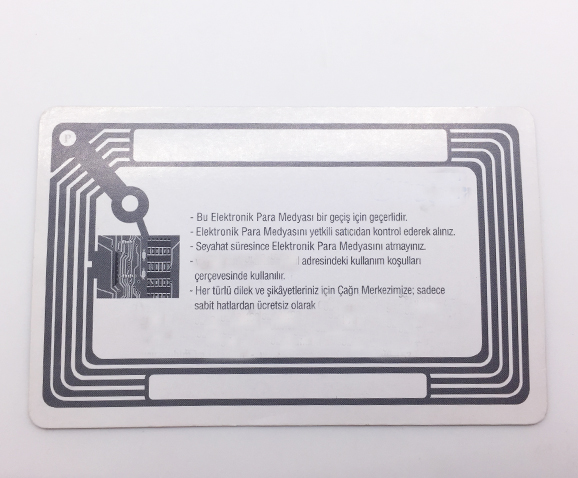

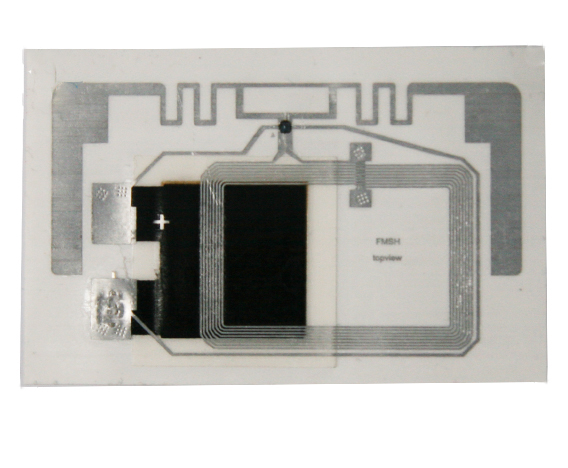

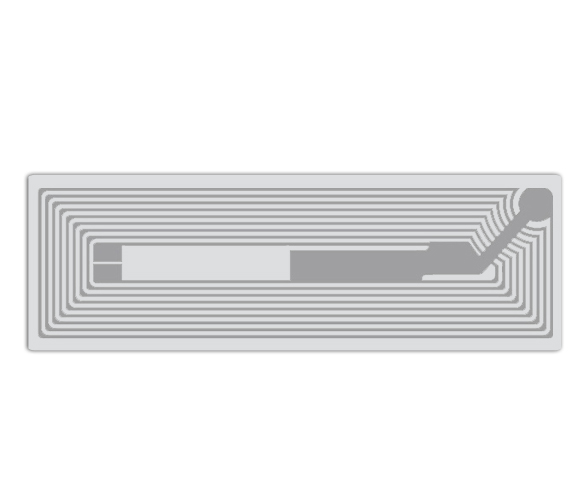

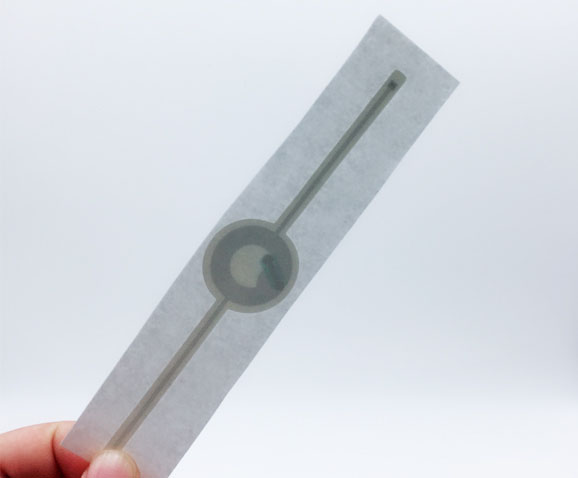

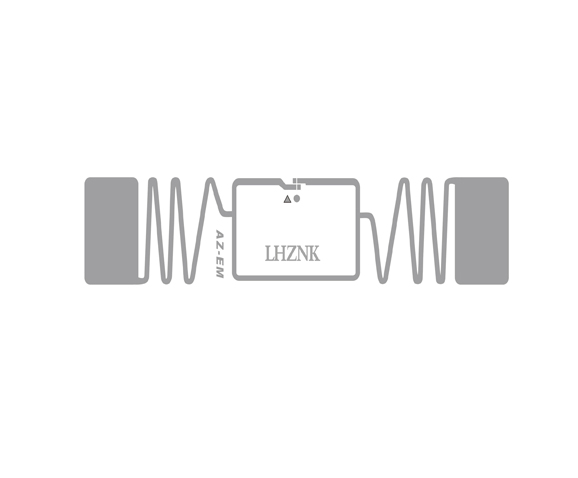

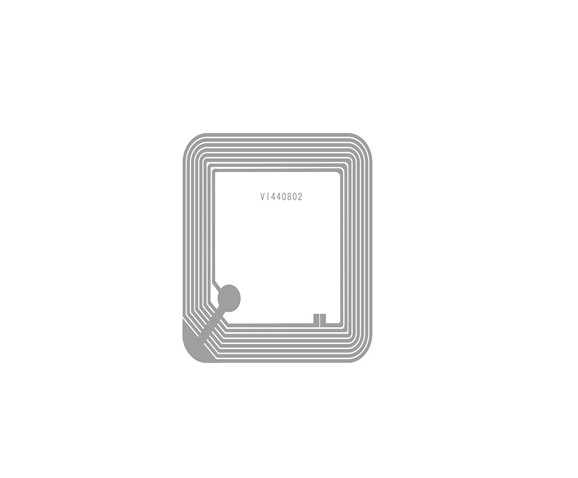

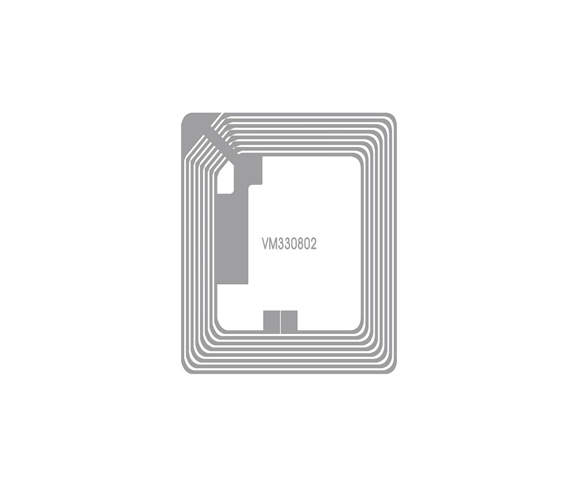

By equipping materials and products with RFID tags, companies can have real-time visibility of the location and status of materials, enhancing the accuracy and speed of material flow. Whether it is raw material supply, production process control, or finished goods delivery, RFID technology can help companies achieve fast and efficient material management, reducing error rates and costs.

2. RFID technology enables the intelligence and visualization of production lines:

Traditional production lines often require manual intervention and operation, which can lead to a lot of human errors and then production interruptions. RFID technology allows for automatic identification and scheduling of equipment, reducing the impact of human factors on production lines. By installing RFID readers on equipment, companies can monitor the operating status, production progress, and anomalies in real-time, enabling early warnings and appropriate actions to ensure stable and efficient production line operations.

3. RFID technology supports traceability and quality control for production lines:

Each product is equipped with a unique RFID tag, allowing companies to record real-time production processes, process parameters, and quality testing results. In the event of quality issues, companies can quickly locate the problem using RFID technology, enabling traceability and recalls, thereby reducing quality risks and losses.

In practical applications, a certain automotive manufacturing company has achieved significant results using RFID technology. Material management accuracy and efficiency have greatly improved, and the stability and operational efficiency of the production line have significantly increased. Furthermore, due to RFID technology's intelligent scheduling and monitoring capabilities, the production cycle has been greatly reduced, production capacity has been fully utilized, and the company's production efficiency and competitiveness have significantly improved.

Before adopting RFID technology, the automotive manufacturing company faced significant challenges with large production lines and complex material management. Their material management processes required a considerable amount of manual intervention and manual recording, leading to errors and delays. To improve efficiency and accuracy, the company decided to implement automated material management and tracking using RFID technology.

By equipping each material with RFID tags, the company can track the flow and usage of materials. When materials enter the production line, RFID readers automatically read the information on the tags and associate them with workstations on the production line. In this way, the company can monitor the real-time location and usage of materials, replenish and adjust material supply in a timely manner, and avoid production line downtime due to material shortages. Additionally, the integration of electronic ink screen tags into the production line allows for visualization, paperless processes, and standardized production controls, reducing long-term costs and improving production efficiency.

Moreover, by installing RFID readers on equipment, companies can monitor the operating status and production progress of the equipment in real-time. When equipment abnormalities or failures occur, the RFID system automatically generates alerts and notifies maintenance personnel for prompt resolution, reducing production line downtime and losses caused by equipment failures.

RFID technology brings dual advantages of efficiency and cost reduction to production line management. Through automated and intelligent management, production line efficiency is greatly improved, production cycles are shortened, and production capacity is fully utilized. At the same time, RFID technology reduces manual operations and errors, improving the stability and reliability of the production line while lowering labor costs and losses.

In conclusion, RFID technology is the key to unlocking efficient production line operations. It facilitates automated material management and tracking, intelligence and visualization of production lines, precise product quality control, and cost-effectiveness, helping companies achieve efficient production line operations and enhance competitiveness.

If your company is also facing similar challenges, RFID technology can be the key to unlocking efficient production line operations. Our team has extensive experience and expertise in RFID applications and can provide customized solutions for your needs. Let RFID technology become your production line accelerator, enhancing your competitiveness and performance!

Start With Union Smart--Enjoy The Smart Life! As a company integrating production and sales, our company and factory encompass a total area of 10,000 square meters. With 13 years of experience in manufacturing and selling smart cards and labels, we have established a diverse product lineup that includes a wide range of smart cards and tags. We are committed to continuously improving and believe that our unwavering dedication will allow us to provide a smarter and more environmentally friendly lifestyle to an ever-expanding user base.

1. RFID technology provides automated material management and tracking for production lines:

By equipping materials and products with RFID tags, companies can have real-time visibility of the location and status of materials, enhancing the accuracy and speed of material flow. Whether it is raw material supply, production process control, or finished goods delivery, RFID technology can help companies achieve fast and efficient material management, reducing error rates and costs.

2. RFID technology enables the intelligence and visualization of production lines:

Traditional production lines often require manual intervention and operation, which can lead to a lot of human errors and then production interruptions. RFID technology allows for automatic identification and scheduling of equipment, reducing the impact of human factors on production lines. By installing RFID readers on equipment, companies can monitor the operating status, production progress, and anomalies in real-time, enabling early warnings and appropriate actions to ensure stable and efficient production line operations.

3. RFID technology supports traceability and quality control for production lines:

Each product is equipped with a unique RFID tag, allowing companies to record real-time production processes, process parameters, and quality testing results. In the event of quality issues, companies can quickly locate the problem using RFID technology, enabling traceability and recalls, thereby reducing quality risks and losses.

In practical applications, a certain automotive manufacturing company has achieved significant results using RFID technology. Material management accuracy and efficiency have greatly improved, and the stability and operational efficiency of the production line have significantly increased. Furthermore, due to RFID technology's intelligent scheduling and monitoring capabilities, the production cycle has been greatly reduced, production capacity has been fully utilized, and the company's production efficiency and competitiveness have significantly improved.

Before adopting RFID technology, the automotive manufacturing company faced significant challenges with large production lines and complex material management. Their material management processes required a considerable amount of manual intervention and manual recording, leading to errors and delays. To improve efficiency and accuracy, the company decided to implement automated material management and tracking using RFID technology.

By equipping each material with RFID tags, the company can track the flow and usage of materials. When materials enter the production line, RFID readers automatically read the information on the tags and associate them with workstations on the production line. In this way, the company can monitor the real-time location and usage of materials, replenish and adjust material supply in a timely manner, and avoid production line downtime due to material shortages. Additionally, the integration of electronic ink screen tags into the production line allows for visualization, paperless processes, and standardized production controls, reducing long-term costs and improving production efficiency.

Moreover, by installing RFID readers on equipment, companies can monitor the operating status and production progress of the equipment in real-time. When equipment abnormalities or failures occur, the RFID system automatically generates alerts and notifies maintenance personnel for prompt resolution, reducing production line downtime and losses caused by equipment failures.

RFID technology brings dual advantages of efficiency and cost reduction to production line management. Through automated and intelligent management, production line efficiency is greatly improved, production cycles are shortened, and production capacity is fully utilized. At the same time, RFID technology reduces manual operations and errors, improving the stability and reliability of the production line while lowering labor costs and losses.

In conclusion, RFID technology is the key to unlocking efficient production line operations. It facilitates automated material management and tracking, intelligence and visualization of production lines, precise product quality control, and cost-effectiveness, helping companies achieve efficient production line operations and enhance competitiveness.

If your company is also facing similar challenges, RFID technology can be the key to unlocking efficient production line operations. Our team has extensive experience and expertise in RFID applications and can provide customized solutions for your needs. Let RFID technology become your production line accelerator, enhancing your competitiveness and performance!

Start With Union Smart--Enjoy The Smart Life! As a company integrating production and sales, our company and factory encompass a total area of 10,000 square meters. With 13 years of experience in manufacturing and selling smart cards and labels, we have established a diverse product lineup that includes a wide range of smart cards and tags. We are committed to continuously improving and believe that our unwavering dedication will allow us to provide a smarter and more environmentally friendly lifestyle to an ever-expanding user base.

Inquiry